Maximizing Machine Performance: A Closer Look at Our Spindle Monitoring Solutions

|7 November 2023Improve your maintenance and operational practices to reduce costs and increase returns for both users and builders of machines. The spindle is a critical component of machine tools, and by monitoring it properly, you can extend its lifespan, plan repairs or replacements more efficiently, and minimize unexpected downtime. Learn more about how our spindle monitoring service and techniques can help you maximize machine tool performance, achieve greater efficiency, and save on maintenance and repair costs.

The importance of effective spindle monitoring

Without spindle monitoring, machine tool operators and manufacturers may face a variety of issues that can affect productivity, quality, and profitability. These issues include unexpected downtime, premature wear, and increased repair costs. Safety risks and reduced competitiveness are other downsides of overlooking spindle monitoring.

On the other hand, inadequate or ineffective spindle monitoring can lead to data overload, confusion, and misinterpretation, as well as increased maintenance and repair costs. Achieving optimal spindle performance requires a careful balance of proper monitoring, data analysis, skilled maintenance and repair, and a commitment to continuous improvement. It also takes a deep level of understanding and expertise of the machine-domain.

IPercept’s solution for spindle monitoring

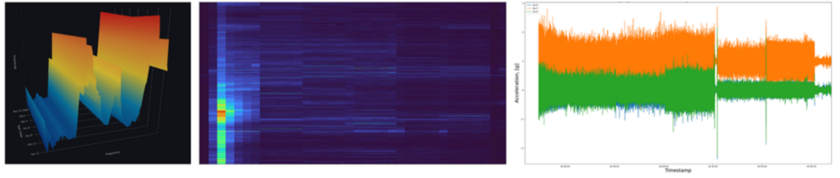

This is where we come in! We have spent years researching and developing advanced automated data analysis for the manufacturing industry. First, we apply our domain knowledge and experience to identify criticalities and root causes of failures in spindles. Then we customize our smart machine learning algorithms to detect and provide recommendations on how to solve those machine-specific problems.

We perform discrete testing, which can either be carried out manually by an operator during maintenance windows or automatically triggered based on certain predefined parameters, saving time and allowing more focus on other things. As part of these discrete tests, we apply our patented test cycle, which we have adapted over years of research, allowing us to perform root cause analysis on a component level and identify trends, thresholds, alarms, and alerts. Through our services, we have been able to extend the life of spindles, better plan for their repair or replacement, and ensure that they do not fail unexpectedly.

This is achieved by retrofitting the machine with our machine-configured Smart IIoT Device, which is equipped with micrometer-accurate vibration and motion sensors and data acquisition system. Production data is not recorded, and this means that cybersecurity is an important benefit of the service. The device also does not require any connection to the IT infrastructure, Wi-Fi, or the machine controller.

It is truly plug-and-play, with installation and set-up times as short as an hour. Our advanced and patented algorithms then analyze and monitor the test cycles. This allows for more meaningful insights into maintenance and operations. These insights, along with other notifications, alerts, or alarms, can be viewed directly on our dashboard and additional discussions and deeper insights are shared through presentations and meetings.

“With IPercept’s services, we can plan for the right maintenance actions at the right time, resulting in better productivity and lower costs.”

– Senior Production Manager, Automotive Manufacturing Company.