Some numbers to back it up

5-40%

Reduction of

Planned Downtime

1-20%

Increase in OEE

(Overall Equipment Efficiency)

20-60%

Reduction in

Replacement Components

30-80%

Reduction of

Un-Planned Downtime

IPercept IIoT Device

- Machine-configured smart IIoT device and system with market-leading sensitivity and accuracy

- Plug-and-Protect system, with a one-hour installation time for any machine

IPercept Analytics

- Industrial routers establish instant communication with our platforms

- Based on 7 years of R&D, our patented algorithms analyze data from test cycles

- Insights delivered in 3 weeks, without extensive training

IPercept Applications & Services

- Insights/Work Orders on maintenance

- Insights/Work Orders on operations

- Notification and alarms

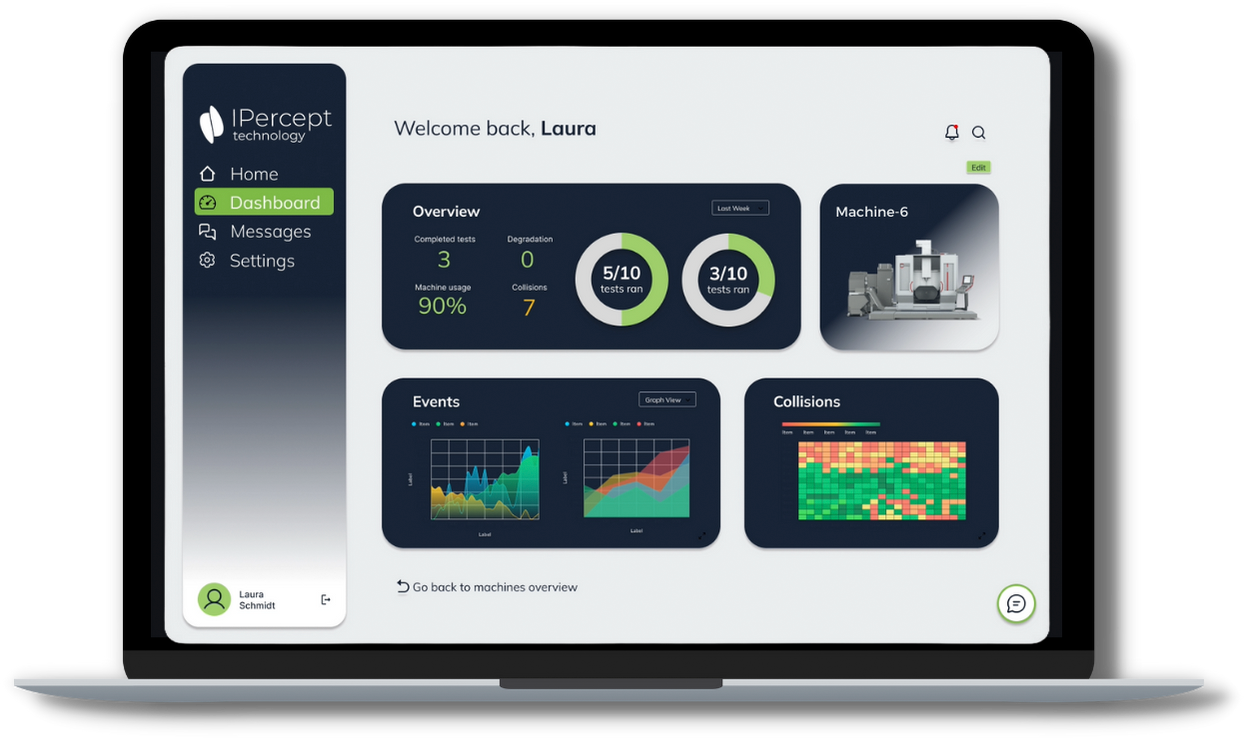

- Customized Dashboards

- Integration with MES/EAM/ERP

The Augmented Perception Platform (APP) is end-to-end, which means that it encompasses the entire functional spectrum, from sensor integration to analytics and digital twin workflow deployment, visualization dashboards, alerting, and reporting.

The Fitness Tracker of Industrial Machines

Fine-tuned smart IIoT device equipped with market-leading motion and vibration sensor technology. It is designed for effortless retrofitting with its self-configuration technology, resulting in only one-hour of installation time. All solutions can be enabled with just one device per mechanical system. Additionally, it seamlessly enables wireless connectivity with our platforms.

What sets it apart is the straightforward installation (only a 24V power supply is required), with no need for machine controller integration, ensuring cyber security without any IT integrations.

IPercept Analytics

Our patented algorithm, based on 7 years of R&D, analyzes data from test cycles captured by the Fitness Tracker. We generate a physics-based virtual model of the machine, or digital twin, with which we can compare its expected behavior with its actual performance in reality. After a quick calibration period (approximately 3 weeks), insights are delivered relating to the absolute (not just relative to a baseline) status of the machine.

IPercept Applications

& Services

Dashboards that are customized or integrated to provide insights into maintenance and operations. Enables notifications and alarms, as well as degradation stages and trends. Integration with MES/EAM/ERP systems is also an option.

01

We understand your machines

Our team is built with the careful integration of mechanical engineers and data scientists who have a deep domain understanding of the unique mechanical attributes of your machines.

02

Hardware Enabled SaaS

The right quality and structured data, complying with industrial requirements, is a must for a successful application. For this reason, IPercept could have never been born as a pure software company. You can imagine our IIoT Device as a smart fitness tracker, which can easily enable all the necessary software applications to improve the efficiency of your machines.

03

Experience-Driven AI

Every machine is unique, and they need highly customized solutions. But every machine is composed of a small number of mechanical subsystems (e.g., linear, rotary axes, or spindles). After long years of R&D work, we created our algorithms to be self-configured to all the key mechanical subsystems and, therefore, to all machines. Key to this are the fine-tuned machine learning algorithms, which leverage domain knowledge. Without speaking the languages of mechanical engineers, no real actionable insight can be provided for complex industrial machines.

04

Large Machine Models

IPercept is building up the world's first Large Machine Models corresponding to various mechanical subsystems. These models are trained on massive amounts of proprietary data with the right quality. Our customers stay years ahead of the improvement curve, leveraging hundreds of use cases and continuously growing experience embedded in our Large Machine Models.